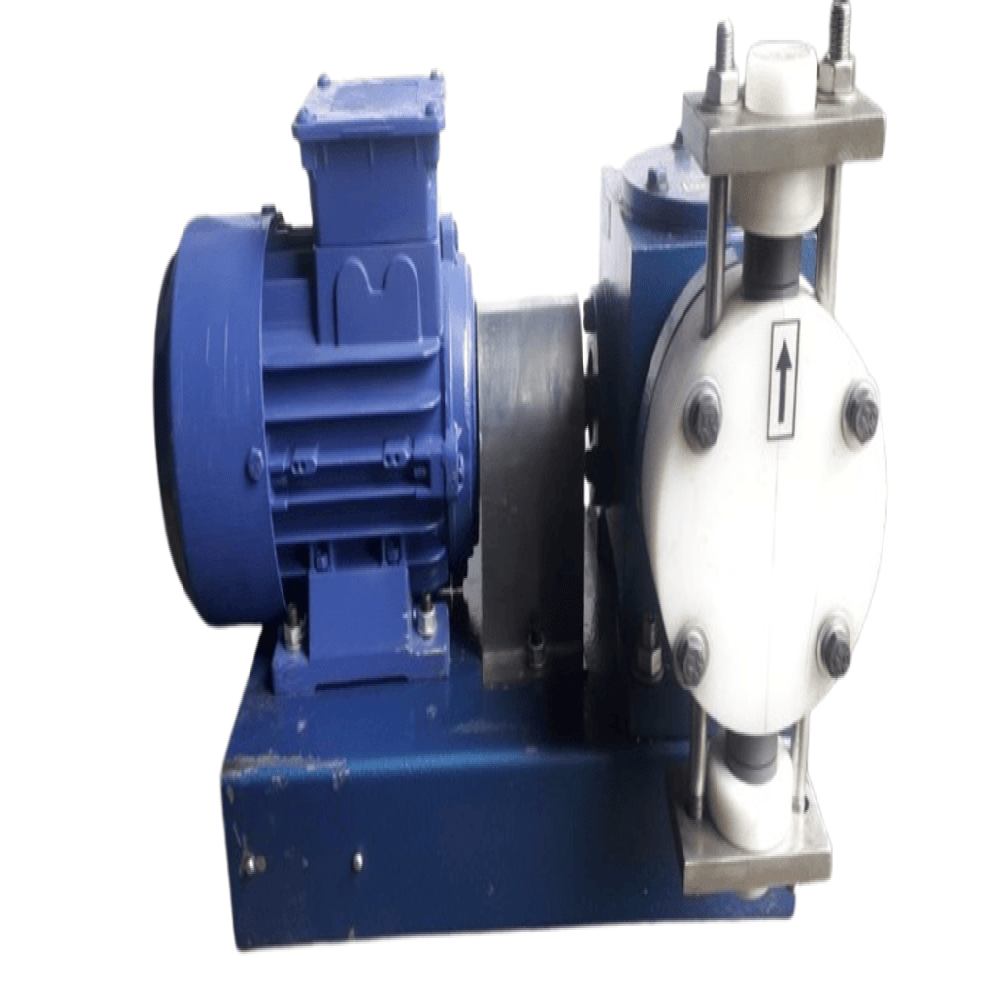

Pressure Plunger Pump

Product Details:

- Flow Rate 200 LPH

- Theory Reciprocating Pump

- Discharge Pressure 5 KG/CM2

- Inlet/Outlet 1/1

- Head Size 85MM

- Usage DOSING PUMP IS USED FOR CHEMICAL DOSING

- Material PP

- Click to View more

Pressure Plunger Pump Price And Quantity

- 1 Set

- 22500.0 INR/Set

Pressure Plunger Pump Product Specifications

- PP

- RUBBER SEAL

- 5 KG/CM2

- Reciprocating Pump

- DOSING PUMP IS USED FOR CHEMICAL DOSING

- ISO 9001:2015

- 30 Drams (dr)

- DOSING PUMP

- 1/1

- 85MM

- DARK BLUE

- Diaphragm Pump

- Other

- DOSING SUCTION

- 200 LPH

Pressure Plunger Pump Trade Information

- 100 Set Per Day

- 1 Days

- All India

Product Description

Pressure Plunger Pump

Our company deals in the manufacturing and supplying of top quality Pressure Plunger Pump which is designed as per the industrial standards by using top grade highly rigid cast iron which imparts greater tensile as well as compressive strength to withstand high pressure values. The whole assembly is coated with an anti-corrosive paint coating to prevent surface damages due to rust and corrosion. This industrial machine requires very less maintenance and electrical power which makes it cost effective in operation.

Technical Specifications

|

Brand |

Mini Dose Solution Pumps |

|

Model |

MD-2 |

|

Max Flow Rate |

200 LPH |

|

Material |

Cast Iron |

|

Automation Grade |

Automatic |

|

Power Source |

Electric |

|

Dosing Flow Rate |

200 LPH |

|

Voltage (Volt) |

415 V |

|

Motor Speed (RPM) |

1400 rpm |

|

Pressure (Bar) |

5 kg/cm2 |

Precision Dosing Performance

The Pressure Plunger Pump is engineered to deliver accurate and consistent chemical dosing, essential for various industrial processes. Thanks to its precise diaphragm mechanism and reliable rubber seal, every dosage is delivered with minimal risk of leakage. This ensures chemical integrity and operational safety, making it optimal for manufacturing, water treatment, and process lines.

ISO 9001: 2015 Standard Compliance

Certified under ISO 9001: 2015, this dosing pump upholds rigorous quality standards, guaranteeing reliable performance and product consistency. The structure and components are selected to ensure durability and ease of maintenance, providing customers with peace of mind and long-term operational value.

FAQs of Pressure Plunger Pump:

Q: How does the Pressure Plunger Pump facilitate chemical dosing?

A: The pump operates using a diaphragm mechanism powered by electricity and delivers chemicals via a reciprocating action. This ensures precise control over the volume and timing of each dose, making it ideal for regulated chemical dispensing.Q: What industries commonly use this low-pressure dosing pump?

A: Industries such as water treatment, chemical manufacturing, and process engineering frequently employ this dosing pump for accurate and safe chemical injection into systems.Q: When should maintenance be performed on the Pressure Plunger Pump?

A: Regular maintenance should follow the manufacturers recommendations, typically after extended operational periods or whenever a drop in flow rate or pressure is noticed. Check seals and diaphragms routinely for wear.Q: Where can I purchase the Pressure Plunger Pump?

A: The pump can be sourced from authorized distributors, manufacturers, suppliers, and traders specializing in industrial dosing equipment.Q: What is the process for installing this dosing pump?

A: Installation requires connecting the 1/1 inlet/outlet ports to compatible piping, securing the pump, and providing suitable electric power. Follow the supplied guidelines to maximize dosing efficiency and safety.Q: What are the benefits of using a diaphragm pump with rubber seals?

A: The diaphragm design and rubber seals enhance leak prevention, chemical resistance, and pump longevity, ensuring reliable performance even with aggressive dosing chemicals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS