Screw Pumps

Product Details:

- Caliber BULE

- Flow Rate 0-1000LPH

- Theory Other

- Discharge Pressure 5 KG/CM2

- Material SS316

- Structure Screw Pump

- Product Type ETP /STP PALANT

- Click to View more

Screw Pumps Price And Quantity

- 1 Piece

- 35500 INR/Piece

- 32500.00 - 32000.00 INR/Piece

Screw Pumps Product Specifications

- Cryogenic

- Diesel

- BULE

- SS316

- 5 KG/CM2

- Water, Paper Printer

- Other

- Screw Pump

- ETP /STP PALANT

- SS316

- 0-1000LPH

- 20KG Kilograms (kg)

- BULE

Screw Pumps Trade Information

- Others

- 100 Piece Per Day

- 2 Days

- No

- WOODEN BOX

- All India

- ETP OR STP PALANT KE LIYE

Product Description

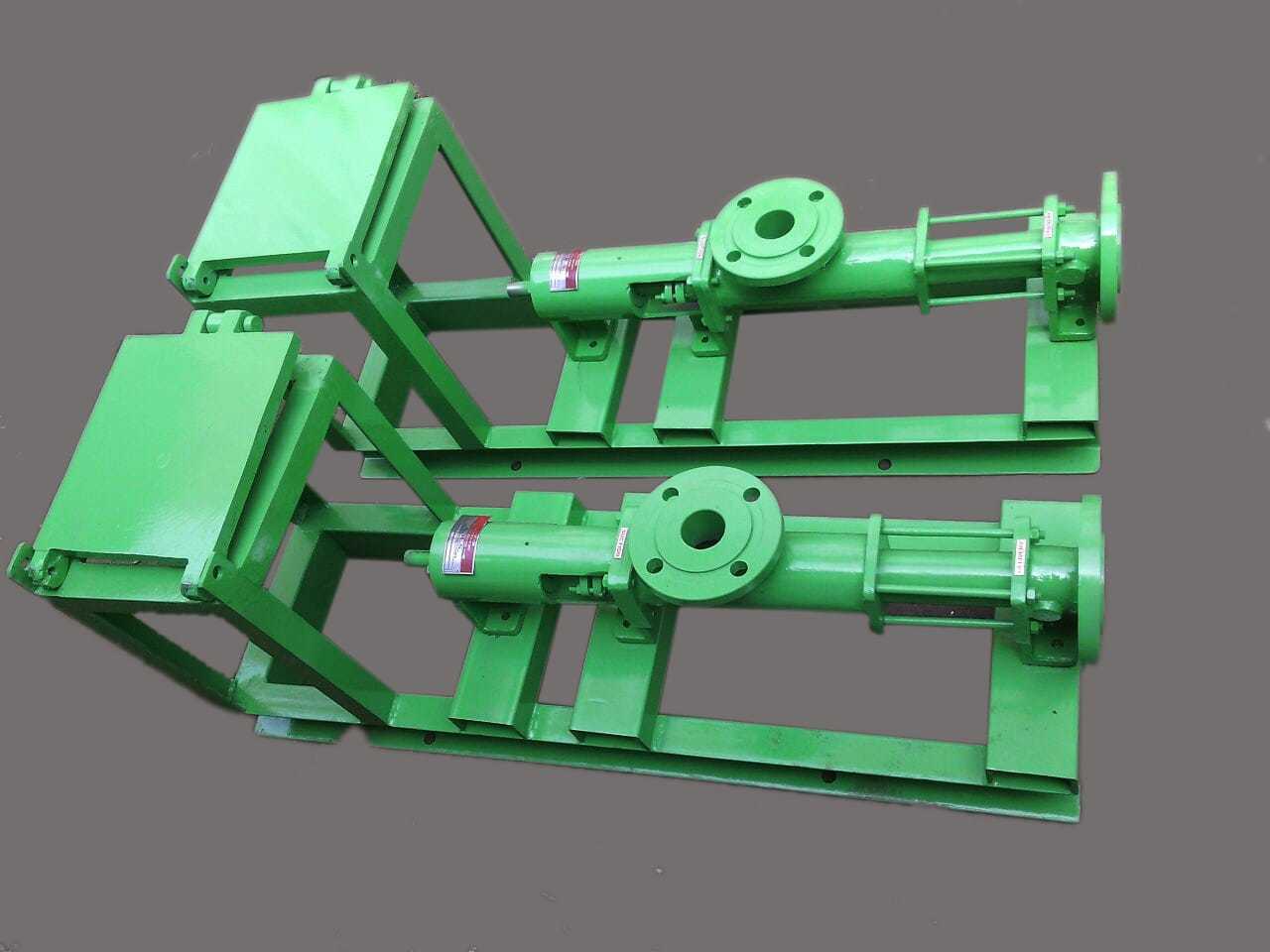

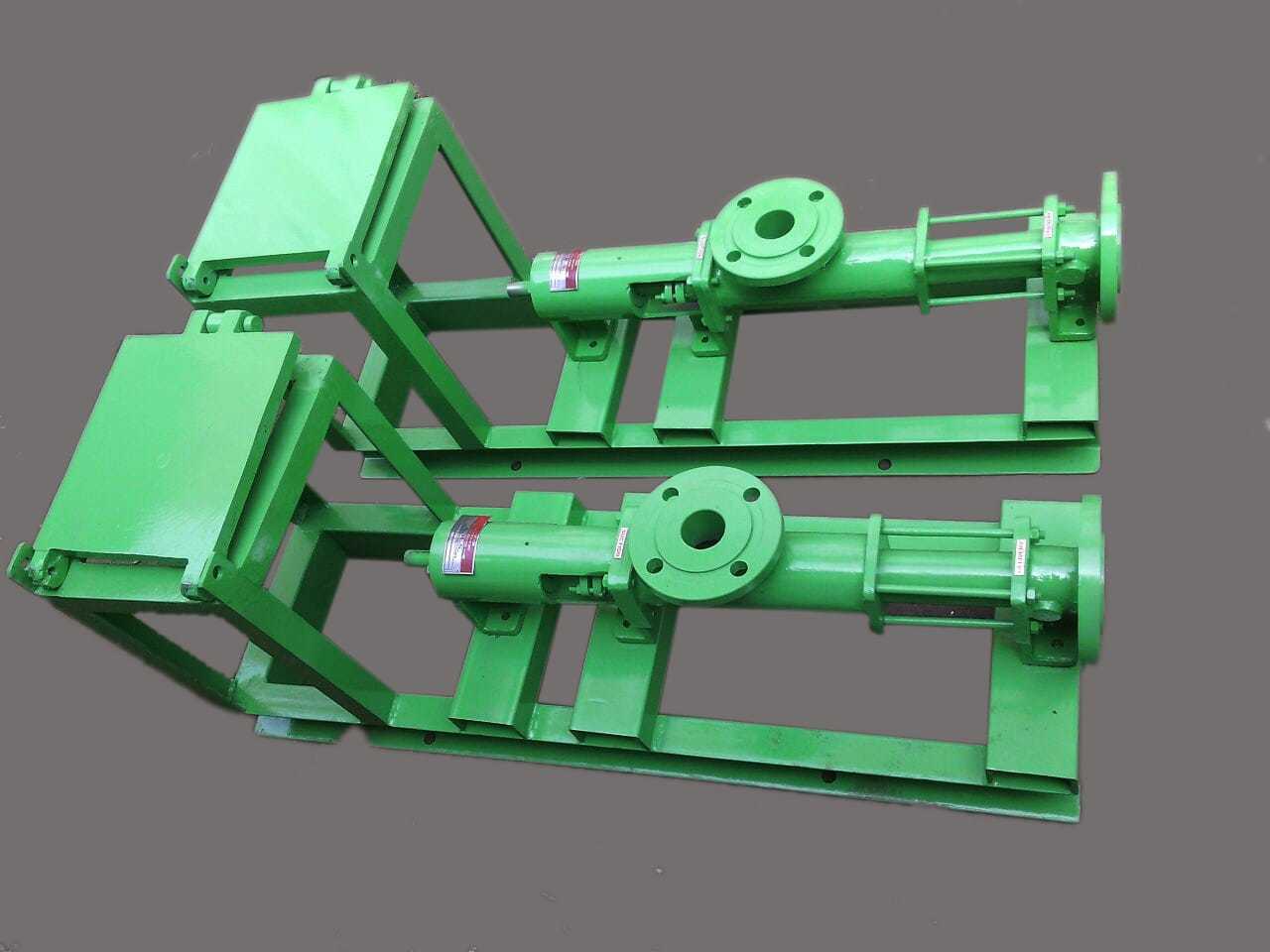

Screw Pumps

Screw Pumps is a premium class liquid transportation machine which is used for the linear discharging of the water, chemical and various other types of liquids. It consists of a large rotating screw which is enclosed in a hollow cylindrical casing through which the fluid passes. It is equipped with ahigh speed electrical motor which gives the rotational power to the screw to move liquids. The component parts are fabricated by using top grade materials which imparts greater strength and rigidity.

Technical Specifications

|

Minimum Order Quantity |

1 Unit |

|

Brand |

Mini Dose |

|

Condition |

New |

|

Automation Grade |

Automatic |

|

Body Material |

Stainless Steel |

|

Cooling Method |

Water Cooled |

|

Fuel Type |

Electricity |

ROTOMAX PUMPS brings together its proven technology, engineering expertise and its quality manufacturing to offer you its Standard Progressive Cavity Pumps.This reliable series finds itself ideal for a wide variety of applications where cost effectiveness is paramount availability of installation space is limited.

Engineered for Demanding Applications

The SS316 screw pumps are specifically built for high-pressure and cryogenic operations. Whether for water treatment, sewage plant processing, paper printing, or fuel handling, their rugged construction and corrosion resistance ensure safe and stable workflows. Their strength serves diverse industries requiring efficient, precise liquid handling.

Flexible Flow and Easy Integration

With an adjustable 01000 LPH flow rate and compatibility with electric systems, these screw pumps offer seamless integration into existing setups. Their efficient design simplifies installation, operation, and maintenance, ensuring a quick start and minimal downtime for your facility.

FAQs of Screw Pumps:

Q: How are SS316 screw pumps installed in water treatment and fuel systems?

A: SS316 screw pumps are installed into water treatment (STP/ETP) or fuel systems using standard pipeline connections. Their compact structure allows for straightforward integration, typically mounted securely with appropriate flanges or fittings and connected to the facilitys electrical supply for automatic or manual operation.Q: What types of fluids can these screw pumps handle effectively?

A: These pumps are suitable for a wide range of liquids, including water, diesel fuel, and process fluids used in paper printers or cryogenic systems. The SS316 material and high-pressure seal design protect against corrosion and leakage, making them ideal for both neutral and aggressive fluids.Q: When is the optimal time to use a high-pressure screw pump in industrial processes?

A: High-pressure screw pumps are optimal when a consistent, leak-free flow is essential, such as during continuous operations in water treatment plants, paper printing, or diesel fuel transfer. Their robust design ensures reliable performance even under fluctuating or extreme process conditions.Q: Where can these screw pumps be effectively deployed within a facility?

A: These pumps can be installed at fluid intake points, transfer stations, or as part of the main flow lines in STP/ETP units, water processing, or paper printing press systems. Their high-pressure tolerance makes them suitable for both primary and auxiliary pumping roles.Q: What is the process for maintaining these SS316 screw pumps?

A: Maintenance involves regular inspection for seal integrity, periodic lubrication of moving parts, and cleaning of the pump housing to remove debris. Given the SS316 and high-quality seal construction, maintenance intervals are typically longer, enhancing pump longevity and reducing downtime.Q: How does using an SS316 screw pump benefit industrial operations?

A: Using an SS316 screw pump offers significant benefits, including robust corrosion resistance, dependable high-pressure handling, smooth flow, and operational reliability. This results in reduced maintenance costs, improved safety, and process efficiency across diverse industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS