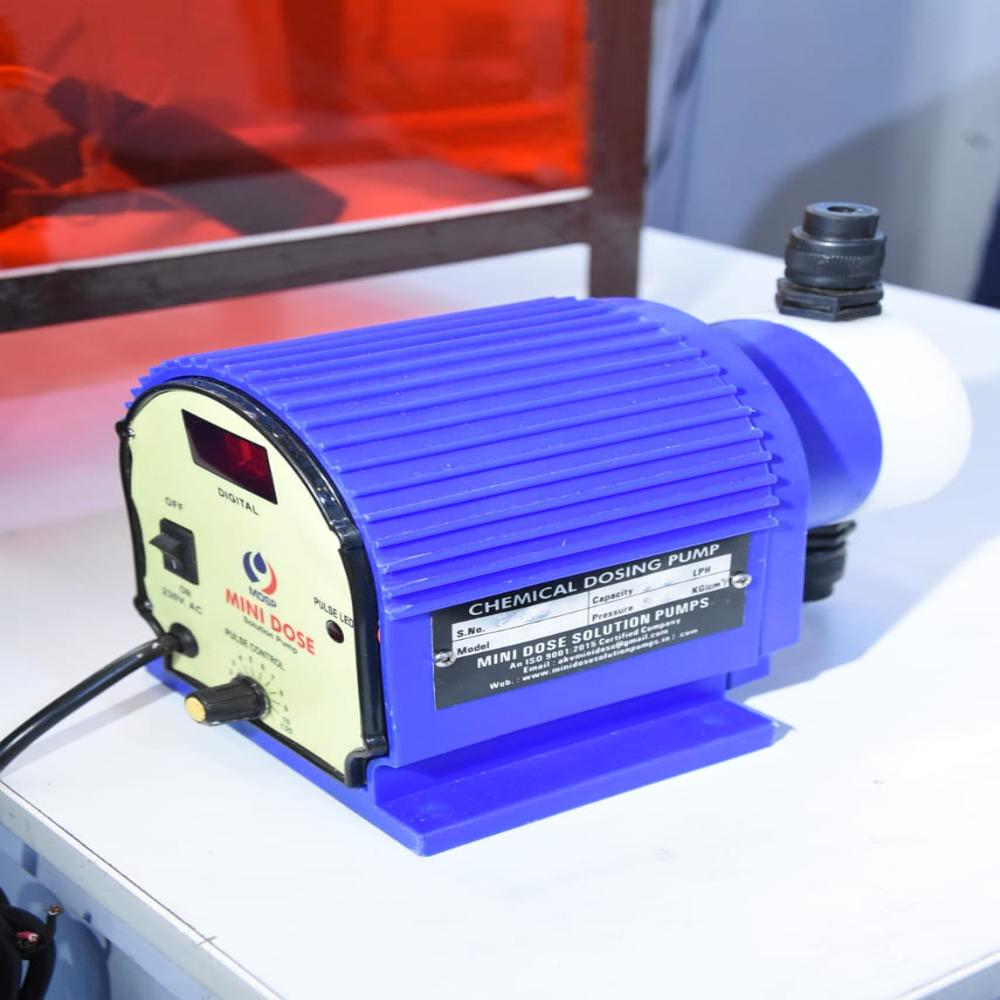

Electronic Dosing Pumps

Product Details:

- Discharge Pressure 3 kg/cm2

- Flow Rate 0-6 LPH

- Head Size 75 MM

- Usage DOSING PUMP IS USED FOR CHEMICAL DOSING

- Structure Diaphragm Pump

- Standard ISO 9001:2015

- Product Type DOSING PUMP

- Click to View more

Electronic Dosing Pumps Price And Quantity

- 1 Piece

- 3000.00 - 3500.00 INR/Piece

- 3500.0 INR/Piece

Electronic Dosing Pumps Product Specifications

- DOSING PUMP IS USED FOR CHEMICAL DOSING

- DOSING SUCTION

- 3 Kilograms (kg)

- Diaphragm Pump

- ISO 9001:2015

- DARK BLUE

- Other

- 75 MM

- DOSING PUMP

- 3 kg/cm2

- 0-6 LPH

Electronic Dosing Pumps Trade Information

- 100 Piece Per Day

- 2 Days

- All India

Product Description

Micro Electronic Dosing Pump

Micro Electronic Dosing Pump is a compact and light weight device which is designed for various kinds of industrial systems for the discharging of calculated amount of liquids such as chemicals, oils and other chemistry agents for the applications which includes water disinfection, chemical processing and many more. It is equipped with an integrated electronic chip for the safe and efficient functioning of the pumping unit.The outer casing is fabricated by using premium quality poly propylene which offers excellent protection against the impacts of moisture and liquid attacks.

Technical Specifications

|

Stroke Controller |

5-100 |

|

Suction Tubing |

7 mm |

|

Voltage |

230 V |

|

Dosing Flow Rate |

0-6 LPH |

|

Brand |

MINI DOSE |

|

Model |

MED -05 |

|

Max Flow Rate |

0 TO 6 PLH |

|

Head |

PP |

We are offering Electronic Dosing Pump to our clients.

Precision Chemical Dosing

Engineered with a diaphragm structure and robust build quality, this dosing pump allows for accurate chemical dispensing and mixing. Its low-pressure design and ISO 9001: 2015 certification ensure consistent operation and quality assurance across various environments.

Efficient and Versatile

Thanks to its electric drive and 0-6 LPH flow rate, the pump adapts easily to different dosing requirements. The 75 mm head size offers reliable output, while the compact 3 kg frame makes it convenient for installation in limited spaces.

FAQs of Electronic Dosing Pumps:

Q: How does the diaphragm structure of the electronic dosing pump enhance chemical dosing accuracy?

A: The diaphragm structure ensures precise control of liquid flow, minimizing leaks and fluctuations, which leads to consistent chemical dosing accuracy for sensitive processes.Q: What are the main benefits of using a low-pressure dosing suction system in chemical applications?

A: Using a low-pressure dosing suction system reduces risk of over-pressurization, supports gentle chemical handling, and helps protect delicate system components, resulting in safer and more reliable operation.Q: When should you opt for this ISO 9001: 2015 certified pump in your dosing applications?

A: This pump is ideal for situations requiring proven quality standards, precision dosing (0-6 LPH), and reliability, such as water treatment, industrial chemical processes, or laboratory experiments.Q: Where can the electronic dosing pump be installed for optimal performance?

A: It can be installed in chemical processing facilities, water treatment plants, laboratories, and any environment where accurate and controlled chemical dosing is required.Q: What is the recommended process for setting the flow rate of the dosing pump?

A: Set the desired flow rate within the 0-6 LPH range via the pumps electronic controls, ensuring the system is calibrated according to your applications dosing requirements.Q: How is the dosing pump used for chemical dosing tasks?

A: The pump is utilized to dispense chemicals accurately into pipelines, tanks, or reactors by adjusting its flow and suction parameters to ensure precise dosages for safe and effective chemical reactions.Q: What are the usage advantages for distributors, manufacturers, and suppliers?

A: Distributors, manufacturers, and suppliers benefit by offering a reliable, ISO-certified dosing pump, providing customers with a trusted solution for various chemical dosing needs and supporting safe, effective automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS