Industrial Dosing Pumps

8000.0 INR/Unit

Product Details:

- Inlet/Outlet 1/1

- Theory Other

- Flow Rate 30 LPH

- Discharge Pressure 4 KG/CM2

- Head Size 85MM

- Material Mild Steel

- Structure Diaphragm Pump

- Click to View more

X

Industrial Dosing Pumps Price And Quantity

- 8000.0 INR/Unit

- 8000.00 - 7500.00 INR/Unit

- 1 Unit

Industrial Dosing Pumps Product Specifications

- 1/1

- 3 Kilograms (kg)

- Other

- DOSING PUMP

- RED

- Diaphragm Pump

- RUBBER SEAL

- Other

- Water

- ISO 9001:2015

- 30 LPH

- Mild Steel

- DOSING SUCTION

- 85MM

- 4 KG/CM2

Industrial Dosing Pumps Trade Information

- 100 Unit Per Day

- 2 Days

- No

- Contact us for information regarding our sample policy

- All India

Product Description

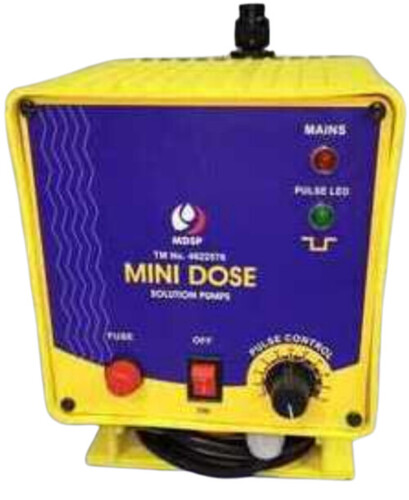

Technical Specifications

|

Brand |

Mini Dose |

|

Condition |

New |

|

Material |

Mild Steel |

|

Power Source |

Electric |

|

Automatic Grade |

Automatic |

|

Installation Service |

Yes |

|

Automation Grade |

Automatic |

Reliable Chemical Dosing Solutions

Our industrial dosing pumps are engineered to deliver precise, low-pressure dosing of chemicals and water, offering increased efficiency and accuracy for a wide range of industrial applications, including water treatment facilities and manufacturing processes. Built from mild steel, they provide exceptional resistance to corrosion and long-lasting operation.

Versatile Applications Across Industries

These dosing pumps serve various sectors, from water purification plants to chemical manufacturing units. Their adaptability stems from a robust design and standardized power configuration, making them suitable for both new installations and integration into existing systems. Distributors, manufacturers, suppliers, and traders trust their reliability and efficiency.

FAQs of Industrial Dosing Pumps:

Q: How do industrial dosing pumps operate when used for water and chemical dosing?

A: Industrial dosing pumps use an electric motor to drive a pumping mechanism that delivers a precise quantity of fluids, such as water or chemicals, at low pressure. The process ensures consistent and accurate dosing while minimizing waste.Q: What are the main benefits of using mild steel dosing pumps in industrial settings?

A: Mild steel dosing pumps provide excellent durability and resistance to wear, making them suitable for continuous industrial use. Their robust construction supports long service life, even when handling aggressive chemicals or frequent operation cycles.Q: When is it appropriate to use an industrial dosing pump for chemical dosing purposes?

A: An industrial dosing pump is best employed whenever precise, controlled addition of chemicals is required, such as in water treatment plants, process industries, or production lines where accuracy and repeatability are critical to the process.Q: Where can these dosing pumps be installed within an industrial facility?

A: Dosing pumps can be installed at points where exact dosing of water or chemicals is required, such as in mixing tanks, water treatment lines, or upstream of reactors. Their compact design allows flexible placement in new or existing setups.Q: What is the standard process for maintaining an industrial dosing pump?

A: Regular maintenance involves checking and cleaning the pump head, verifying calibration accuracy, ensuring electrical connections are secure, and inspecting for signs of corrosion or wear, especially when handling corrosive chemicals.Q: What industries typically benefit from sourcing these dosing pumps from a manufacturer, supplier, or distributor?

A: Industries like water treatment, chemical manufacturing, pharmaceuticals, and food processing benefit from sourcing dosing pumps through specialized suppliers, who provide tailored solutions, technical support, and reliable after-sales service.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS