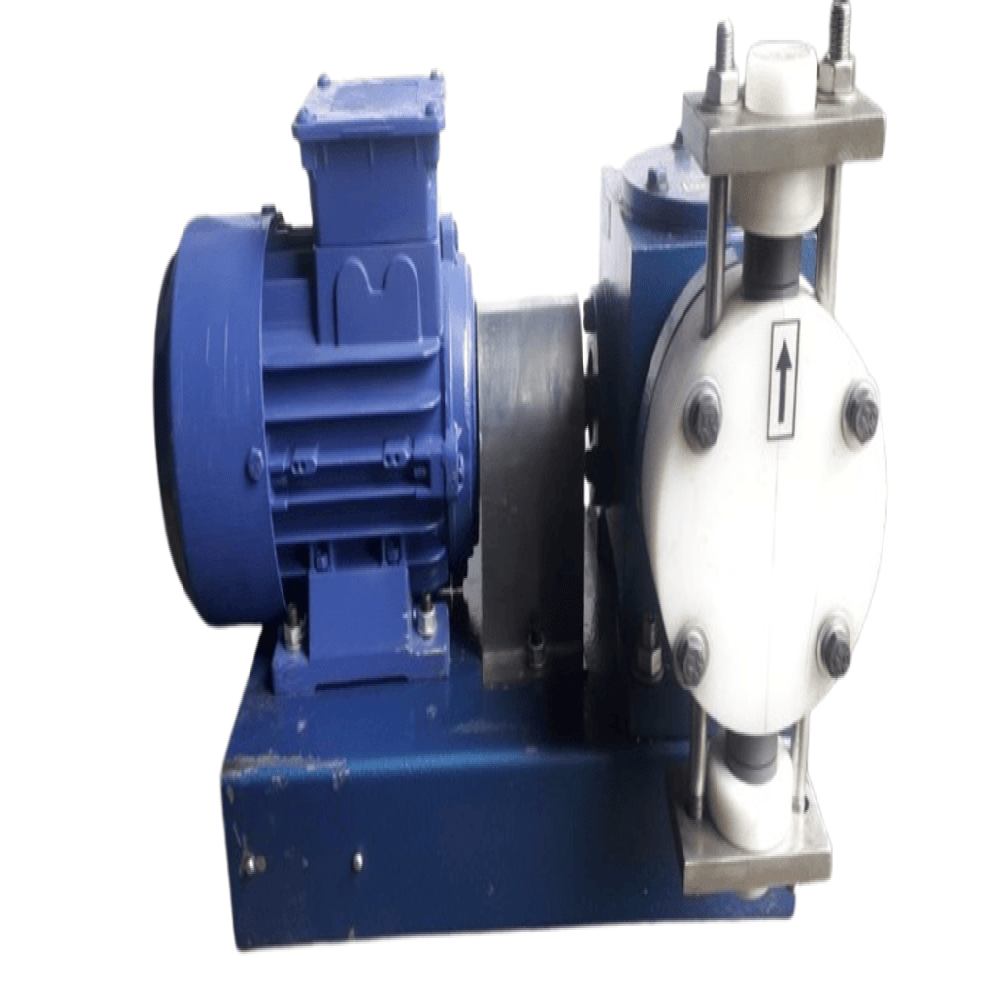

Plunger Pump

Product Details:

- Discharge Pressure 5 KG/CM2

- Inlet/Outlet 1/1

- Theory Other

- Head Size 75 MM

- Flow Rate 250 LPH

- Usage DOSING PUMP IS USED FOR CHEMICAL DOSING

- Material SS316

- Click to View more

Plunger Pump Price And Quantity

- 20000.00 - 20500.00 INR/Piece

- 1 Piece

- 24500.00 INR/Piece

Plunger Pump Product Specifications

- DOSING SUCTION

- Other

- SS316

- M, e, d, i, P, r, e, s, s, u, r, e, u, m, Bar

- RUBBER SEAL

- DOSING PUMP

- 250 LPH

- 75 MM

- ISO 9001:2015

- Cryogenic

- Other

- DARK BLUE

- W, P, O, E, R Volt (v)

- 1/1

- 5 KG/CM2

- 30 Kilograms (kg)

- DOSING PUMP IS USED FOR CHEMICAL DOSING

- Diaphragm Pump

Plunger Pump Trade Information

- Others

- 100 Piece Per Day

- 2 Days

- Yes

- WOODAN BOX

- All India

- STP PLANT USE ONILY plunger type dosing pump that is widely used in chemical industry for transporting chemicals.

Product Description

Plunger dosing pump is a plunger type dosing pump that is widely used in chemical industry for transporting chemicals. This is a positive displacement pump that can handle corrosive, abrasive or viscous fluids. This metering device has hard chrome plated plunger. The other industries that use this pump are pulp & paper, sugar, textile, water treatment, petrochemical, and more. The design of this pump is simple, yet robust. Customers can get this pump in different configurations, from simplex, duplex, triplex to quadriplex.

Technical Specifications

| Minimum Order Quantity | 1 Unit |

| Brand | Mini Dose |

| Material | Cast Iron |

| Condition | New |

| Power Source | Diesel |

| Automation Grade | Automatic |

| Features | Autometic |

Reliable Chemical Dosing Performance

Engineered for accuracy and durability, this plunger pump offers medium pressure dosing with a robust SS316 construction. Its diaphragm design and rubber seal assure reliable usage in cryogenic and industrial processes, maintaining efficiency in demanding environments.

Certified Quality and Safety Standards

Manufactured under ISO 9001: 2015 certification, the pump guarantees standardized quality and operational safety. Whether selected by distributors, manufacturers, or suppliers, clients benefit from rigorous quality control and dependable performance.

FAQs of Plunger Pump:

Q: How does the plunger pump ensure precise chemical dosing?

A: The plunger pump utilizes a diaphragm structure and rubber seals, allowing accurate and controlled dosing for chemical applications with a flow rate of 250 LPH. Its SS316 construction offers resistance to chemicals and maintains dosing integrity even under medium pressure.Q: What is the typical usage for this medium pressure dosing pump?

A: This pump is primarily used for chemical dosing, especially in cryogenic applications. Its precise flow control makes it ideal for industrial settings requiring reliable dosing performance and chemical compatibility.Q: When should the plunger pump be maintained for optimal operation?

A: Routine maintenance is recommended every few months or according to the usage intensity, to inspect rubber seals and ensure the diaphragm structure remains functional. Regular checks help prevent leaks and ensure sustained dosing efficiency.Q: Where can the plunger pump be installed?

A: The pump can be installed in industrial plants, cryogenic facilities, and chemical processing units. Its compact design with a 75 mm head size and medium weight (30 kg) facilitates flexible placement on various equipment and platforms.Q: What is the process for integrating the pump into existing chemical dosing systems?

A: Integration involves connecting the single inlet and outlet (1/1) to the dosing lines, positioning the pump securely, and configuring it for the required flow rate. Ensure compliance with the systems pressure and materials for optimal performance.Q: What are the benefits of choosing a SS316 diaphragm plunger pump for dosing?

A: SS316 offers excellent corrosion resistance, especially when handling aggressive chemicals. The diaphragm design with rubber seals enhances leak prevention, and the certified build (ISO 9001: 2015) guarantees consistent quality and operational safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS