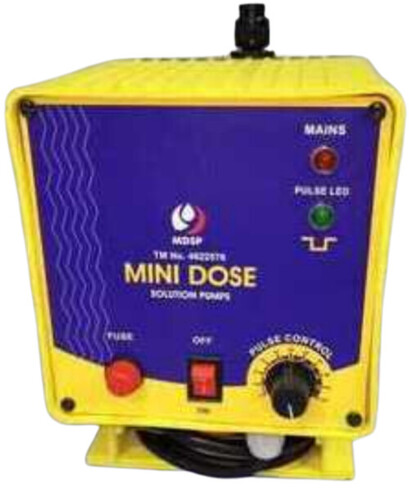

Chemical Dosing Pump

Product Details:

- Head Size 39 MM

- Theory Electromagnetic Pump

- Discharge Pressure 5 KG/CM2

- Caliber BLUE

- Flow Rate 0-30 LPH

- Usage RO PLANT

- Material PP

- Click to View more

Chemical Dosing Pump Price And Quantity

- 8000.0 INR/Piece

- 1 Piece

Chemical Dosing Pump Product Specifications

- Other

- 39 MM

- PP

- RO PLANT

- CHEMICAL DOSING

- BLUE

- 0-30 LPH

- 5 KG/CM2

- 40 LPH

- Diaphragm Pump

- Electromagnetic Pump

- 3 KG Kilograms (kg)

- BLUE

Chemical Dosing Pump Trade Information

- 100 Piece Per Day

- 1 Days

- BOX

- All India

- The offered Electronic Dosing Pump is a compact and sturdy unit used for the discharging of the fluids in calculated volumes for the applications like water treatment, swimming pool chlorination and other kind of chemical processing. It is designed by using top quality materials and highly reliable electronic circuitry for the continuous and safe operation. The whole assembly is enclosed in a heavy duty hard plastic casing which offers excellent protection against the moisture, water and chemical attacks.

Product Description

Chemical Dosing Pump Equipment

Mini Dose Solution Pumps is a leading manufacturer and supplier of industrial grade Chemical Dosing Pump Equipment which is designed by using premium class heavy engineering materials for higher strength and less maintenance which results in longer service life. It is most commonly used in industries such as chemical, pharmaceutical, water treatment plants, paint and oil. The offered machine runs on standard electrical voltage of 220 volts for the safe working of the pumping device.

The offered Electronic Dosing Pump is a compact and sturdy unit used for the discharging of the fluids in calculated volumes for the applications like water treatment, swimming pool chlorination and other kind of chemical processing. It is designed by using top quality materials and highly reliable electronic circuitry for the continuous and safe operation. The whole assembly is enclosed in a heavy duty hard plastic casing which offers excellent protection against the moisture, water and chemical attacks.

Precision Dosing for RO Plants

This chemical dosing pump enables accurate injection of chemicals within reverse osmosis (RO) plants, optimizing treatment processes. Its electromagnetic operation ensures pulse-free, measured dosing, crucial for maintaining water quality and plant efficiency. The diaphragm structure reduces maintenance while providing reliable performance over extended periods.

Robust PP Build for Lasting Durability

Constructed from high-quality polypropylene (PP), the pump withstands aggressive chemicals commonly used in water treatment. This material choice prevents corrosion and ensures a longer operational life, making it ideal for continuous use in demanding environments such as industrial or municipal RO plants.

Versatile Flow & Pressure Management

The dosing pumps flow rate can be easily adjusted from 0 to 6 liters per hour to match process requirements. Its medium-pressure rating accommodates various treatment system sizes, offering dependable operation for both small and large-scale water treatment applications.

FAQs of Chemical Dosing Pump Equipment:

Q: How does the chemical dosing pump work in RO plant applications?

A: The pump utilizes electromagnetic force to drive its diaphragm mechanism, allowing precise dosing of chemicals such as anti-scalants or disinfectants. This ensures optimal chemical levels in the RO system, improving overall water quality and protecting membranes.Q: What materials are used in the construction of the dosing pump and why?

A: The pump body is made from polypropylene (PP), a highly chemical-resistant material, ensuring compatibility with a broad range of chemicals and providing excellent durability against wear and corrosion.Q: When should the dosing pump be serviced or maintained?

A: Routine maintenance is typically performed every few months, depending on chemical usage and operational hours. Regular checks help maintain dosing accuracy and extend the pumps lifespan.Q: Where is this dosing pump best installed within an RO plant setup?

A: This pump is ideally placed on the dosing line just before the membrane feed section, ensuring effective mixing and distribution of chemicals prior to water entering the membrane modules.Q: What is the process for adjusting the flow rate on the dosing pump?

A: Users can adjust the flow rate using the inbuilt control knob, which modulates the electromagnetic pulses, allowing precise regulation of liquid dosing from 0 to 6 liters per hour.Q: How can users benefit from using an electromagnetic diaphragm dosing pump?

A: This pump provides accurate chemical dosing with minimal energy consumption and low maintenance needs, reducing overall operational costs and enhancing the efficiency of the RO plant.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS